Article list

Production Planning - The Supreme Purpose !

In any production organization as well as those in the sphere of services, there are products that are made easier or harder or some with high loss rates (scrap and remedies). In general, it is considered that if we leave Production Planning (PP) to Production, we will only plan products that are easy to make with a small scrap, with a generally high productivity, but to the detriment of those for whom we have demand. On the other hand, PP switched to Logistics can decrease productivity but...Read this article...

Dynamic Array - Unique Sort

We start from the last article on XLOOKUP (https://bit.ly/39dN8yq) and try to solve the problem of extracting unique data and sorting them using the new dynamic array functions. Bonus, an optimization of data validation. This article is for Office 365 users only.Here is the file used for example:http://bit.ly/2UZAEGTProblem 1. Extract unique data. For example, the product list.We want to make a data extraction form (XLOOKUP) where we find out the quantity delivered for a particular product.In...Read this article...

Process Optimization Workshop

On March 12, our company organizes a workshop in Arad at the Continental Forum hotel with the theme "Process Optimization", where we will have as guests: InterMarium Company from Poland, Centro Software from Italy and company Arkite NV from Belgium. This workshop is intended for CEO's, Plant Manager, Operational Manager, Manager Engineering as well as other people who are responsible for improving processes in the factory.InterMarium company from Poland is an IT company that will present a...Read this article...

Dynamic Array – XLOOKUP

What we wanted in the last article (https://bit.ly/2sQCWvL), was done in mid-January: Microsoft has activated the Dynamic Array for all Office 365 users, not just for "Insiders". In the following articles we will describe these new functions. For today, XLOOKUP.As usual, we start from a problem and try to identify the elements to solve.Problem: Data table and extracting information in various situations.Access to the work file:Problem 1. We have a data form, where when choosing the product code...Read this article...

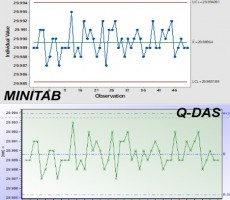

Analysis of Measurement Systems with Q-DAS or MINITAB ?

Measurement systems analysis (MSA) is meant to show us whether the data we use to analyze processes are reliable or not. MSA is a first step that should precede any decision, including the use of Statistical Process Control (stability and capability).There are several software used for statistical data processing. Often used today are MINITAB, Q-DAS but also Excel.Regardless of which software is used to achieve the MSA, all must comply with the standard required by the client, as the case may...Read this article...

Microsoft Power BI

For some time, the area of Business Intelligence has gone from predominantly IT to what we call self-service business intelligence. We need to process and analyze data much more often than we did before, on all levels, not just in the management area. We need to automate our processes and access information faster, in real time. Let's see how Microsoft Power BI can help us.From the beginning we must admit that the old BI solutions were the result of the collaboration between analysts and...Read this article...

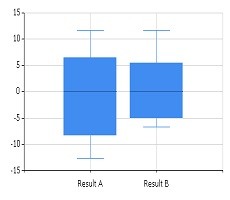

Box Plot Chart

A Box Plot is a type of graph used to show quantitative data patterns. It provides information regarding the central tendency and the shape of the studied distribution.The elements of the Box Plot diagram are:Vmin - The minimum value named and is the smallest value observed in the string of values, excluding outliers;Q1 - The lower quartile delimits the lowest 25% of the observed values;Med - The median delimits 50% of the values (it is exactly halfway between the minimum and maximum...

Read this article...

Teamwork

Teamwork is the collaborative effort of a group to achieve a common goal or to complete a task in the most efficient way.The team receives the goals, understands them and commits to achieving them. Team motivation is strengthened when the organization has clear expectations regarding its work, goals, responsibility and results.From the point of view of team building, they can be homogeneous or heterogeneous. By homogeneity, the team will be much faster aligned with the objectives and the way of...Read this article...

Materials Management Operations Guidelines/Logistics Evaluation V5

Initially defined to establish the requirements of the quality standard in the Automotive Industry for Logistics, MMOG / LE, or the Instructions for Materials Operations Management / Logistics Evaluation, it has become one of the most important tools for standardizing operations in the Automotive industry. The instrument has a multiple role:• Defining a common language throughout the automotive industry regarding otherwise differently perceived notions (eg stock level, recovery plan,...Read this article...

Risk Management

Risk management means identifying, evaluating and prioritizing risks (defined in ISO 31000 as an effect of uncertainty on objectives), followed by a coordinated and economical application of resources to minimize, monitor and control the probability / impact of unfortunate events or to maximize opportunities .The risk management standards have been developed by various institutions, including the Project Management Institute, the National Institute of Standards and Technology, and the ISO...Read this article...

VDA 6.3: 2016 - why do our customers "stress" us?

Life in a provider organization for the automotive industry is very ... alive. You just don't get bored. One of the special moments is when the customer announces that he is following a process audit according to VDA6.3, whether we are talking about a potential analysis or a process evaluation in series production.What and how do you continue? What is this and what does this VDA6.3 help us with?According to VDA6.3, process audit is a method of impartial analysis and evaluation of product...Read this article...

PPAP - Production part approval process

The Production Part Approval Process (PPAP) is designed to demonstrate that a supplier has developed its design and production process to meet customer requirements, minimizing the risk of failure through the efficient use of APQP. Therefore, the request for approval of the new product must be accepted in official PPAP format and with documented results.The latest PPAP edition, published by AIAG, has been completely restructured to describe the requirements regarding the approval of new or...Read this article...

Traceability - curse or blessing? Logistic approach

Traceability is a basic requirement of any industry, in some cases traceability at the batch level is sufficient to meet the requirements, in others it must go in detail and demonstrate that a finished product was made according to the established process, using the materials and quantities established, produced by operators trained to perform those stages of the process, with the recording at the piece level of the date and time of execution of each transformation of the raw material into the...Read this article...

Santa Claus ... hoping to bring us the Dynamic Array

Santa Claus ... hoping to bring us the Dynamic ArrayCareful! This article is for Microsoft Excel-dependent users.Any Microsoft Excel-dependent user wants to be able to benefit from Microsoft's Dynamic Array promises by 2020. Don't you know about them?You had problems with the VLOOKUP function because they didn't even look at the data to the left of the column, you wanted to extract data from a column faster and sort it automatically, you wanted to generate a Data Validation for a much faster...Read this article...

IATF 16949:2016 vs. ISO 9001:2015

Want to access the automotive supplier market?If you are sure you want more projects with large volumes (but with relatively small profit margins and with a few more headaches), the solution is the proper implementation and management of a Quality Management System according to the IATF 16949: 2016 standard.The IATF standard 16949: 2016 is based on ISO 9001: 2015 and defines the requirements of a Quality Management System for the design and development, production and, if applicable, service of...Read this article...

MSA - Open session (Ploiesti)

The practical and interactive applications within the Effective Flux sessions were and are to the taste of all participants 😊.Right now, in Ploiesti, George's expertise is being felt at the Measurement Systems Analysis (MSA) course. At this type of course, participants from various fields (automotive, food, medical, textile, aeronautical) learn how to verify the effectiveness of the inspection.In the interactive part of the session, the application is made, the data is collected and then...Read this article...

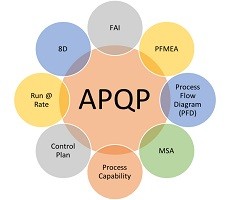

APQP - Advanced Product Quality Planning

APQP (Advanced Product Quality Planning) is a standard designed to support the framing of the launch of a new product as well as the reduction of costs since the product definition phase.Increased product complexity, reduced implementation time and increased competition have a growing influence on the cooperation between car manufacturers and their supply chain. This manifests as intense interactions between the customer and the supplier throughout the product development process, which leads...

Read this article...

Reverse FMEA (RFMEA)

Do you happen to receive complaints from customers, maybe even repeat ones, even though you have implemented P-FMEA risk analysis for production processes? The cause could be given by the purely theoretical realization of these risk analyzes without a practical verification at the workstations (shop floor) of the potential ways of failure.One of the methodologies that can be used to avoid these complaints and to continuously improve the quality of the products is R-FMEA.

R-FMEA helps:

-...

Read this article...

Transport management - suggestions for the future

From the very beginning Supply Chain Management (SCM), whose existence was defined as the process dealing with the management of inventories and costs in the distribution chain, it was observed that the orientation only towards the management of inventories was not sufficient to improve and optimize. logistics costs. Transport management has been and continues to be one of the difficult topics to tackle in logistics.Transport represents 25-30% of the logistics costs of the distribution chain,...Read this article...

QRQC - Quick Response Quality Control

Usually, PROBLEMS are viewed in everyday life as a real pain and something that must be avoided at all costs.In business, PROBLEMS can lead to low productivity, poor quality, high costs and ultimately loss of customers if they are not dealt with quickly and completely prevented their recurrence.The QRQC method can be used for:• resolve and respond to a customer complaint• solve an internal problem, selected on the basis of its importance.It is suitable for problems of medium...Read this article...

Robots - the machines that continue to change our lives

From the construction of the first robot in 1770 that could write a 40-character sentence, made by a Swiss watchmaker, and to this day these machines have been amazingly developed, mainly due to the automation revolution in the industry.A robot is a programmable machine capable of performing a series of actions.Their shape is not unique, it is consistent with the applications it is used for.Currently, the largest spread of robots is in the construction industry, they are now present in any...Read this article...

Preventive maintenance

What does preventive maintenance mean? It is a regularly planned, repetitive activity, made to keep the equipment in working order and to optimize their efficiency and accuracy.This activity involves routine operations such as periodic cleaning, lubrication, testing, calibration and adjustment, wear check and possibly replacement of components.Preventive maintenance is performed while the equipment is functional and has the role of reducing the risk of unexpected failure. It must be planned in...Read this article...

5S - one of the first steps

5S is a powerful LEAN tool, a tool that provides the basis and then a healthy development for a KAIZEN approach to a workplace, a department, a company, and even at the level of civil society. 5S does not only apply to mass productions, large series, small or unique but also in services, administration, medical, banking, wherever there are people, flows and processes.The 5S are the initials of the 5 Japanese words Seiri (Sort), Seiton (Arrange), Seiso (Clean), Seiketsu (Standardization),...

Read this article...

How is Minitab helping us

MINITAB is a statistical software package developed at Pennsylvania State University that has become one of the most widely used in the world.The program is used intensively for various applications such as graphical data interpretation, quality tools (SPC, MSA), Six Sigma and Reliability (maintenance) projects.MINITAB helps us to:• Explore data by graphical analysis: The Pareto chart helps us prioritize project activities, Histograms and Dot Plot are used to show the frequency of...Read this article...

Plastic

Plastics are a constant presence in everyday life, having uses in various fields such as heavy industry, machine building industry (automotive components), food industry (packaging), aeronautical industry, pharmaceutical industry, light industry (goods). consumer goods or toys) and many more.One of the most used techniques for processing plastics is by injection because in this way complex parts with various uses can be obtained as mentioned above.Knowing the classification method, the types,...Read this article...

What is Six Sigma ?

More and more people are learning about Six Sigma.Many people ask themselves, "Would I use a Six Sigma Green Belt or Black Belt certification?" But what does Six Sigma really mean?Jack Welch, president and general manager of General Electric, said that "Six Sigma is a quality program that, when all is said and done, improves your customer experience, reduces costs and builds better leaders."Six Sigma is a process improvement methodology that follows the following 5 steps (DMAIC):Definition:...

Read this article...

FMEA AIAG / VDA

As most of those connected with the automotive world have probably already learned, in June 2019 the first unified edition of AIAG / VDA for the FMEA standard was published.The initial idea that started from this reunification was the standardization of the tables for the evaluation of Severity, Occurrence and Detection, which were treated differently by the North American and European industry, often leading to confusion or high complexity in the product development or improvement activities....Read this article...

Quick Statistics for Minitab

The QUICK STATISTICS application meets the requirements of our customers to significantly reduce the time that engineers spend in collecting, processing and analyzing production data.Access to data: Data extraction takes a few minutes. We use the most common files (csv, txt, xls, etc.).Data filtering: The operator interface allows to choose the data to be analyzed by: car, period, etc.Minitab analysis: We statistically analyze stability and capability.This is an analysis solution that reduces...Read this article...

Who's paying us the salary?

How many times have you heard of colleagues at the Acquisitions as "working for suppliers"? But about my colleagues at Sales as "as if they were working for clients"? In this article we talk about the money that I give to suppliers and customers in the desire to do a good level of service ... and not only. What if I told you that all your employees, as long as they are not supervised, "make gifts" to your clients and suppliers?Read this article...

Modern method of job optimization and error reduction

Effective Flux is in partnership with the producer of a modern technology for organizing the workplace to promote the Romanian market.This method guides operators in their daily collection and assembly tasks to reduce human errors. This leads to improved quality, efficiency and human capital.Read this article...

Introduction to acquisitions

In their long way of transforming raw materials into shining finite products and meeting the needs of the current market, materials and services manage to make the whole world spin around: there are stock exchanges that, through their evolution, make savings to grow and crash, sometimes politically, but often strictly economic, dictated by the market.Read this article...

Production or planned production

Any business that has production units in the back is confronted with a major problem: rational and efficient sharing of resources (people, cars, materials and financial). This division aims to maintain the business in a competitive environment and in a permanent change. Customers and their customers are increasingly demanding variations and flexibility, and they can only be met by maintaining and improving the price of the product or service we sell.Read this article...

CEN/TS 17091:2018

December 11th, 2018, Deloitte Office, London – in front of an highly interested audience, which was also bearing worries related to the consequences of the fast-approaching Brexit, CEN/TS 17091:2018 was officially released.

The standard aims to bring out directions and steps for crisis management, regardless the size and complexity of the organisations and their activities.

Read this article...

Cluj interactive workshop 28.09.2018

Update (17.09.2018)Find out more about this event.Read this article...

Workshop Arad 16.03 - Optimization and quality for your business

On March 16, 2018, Effective Flux organized the interactive workshop "Optimizing and Quality for Your Business".The session took place at the Continental Forum Hotel in Arad.The Practical Seminar has been geared towards leading companies and was an excellent opportunity to understand how we can become more productive without large investments, but also for networking.Among the topics addressed were:- Value Added. Waste identification. Techniques to reduce waste. Lean production systems....Read this article...

Workshop - Optimization and quality for your business

On 29.11.2017, Effective Flux with the support of the Iasi Chamber of Commerce and Industry organized the workshop "Optimization and Quality for Your Business".The topics discussed were:- Value Added. Waste identification. Techniques to reduce waste. Lean production systems. Implementation.- The quality. Efficacy vs. Efficiency. Quality Link - Lean Production System.- Common Problem Solving Techniques: 5 What, Ishikawa, Brainstorming, PDCA, 8D, Six Sigma. Advantages and disadvantages in use.We...Read this article...

QC Story

QC story is a systematic methodology commonly used in practical procedures and practical methods of problem solving in team.It appeared at the Seisakusho Li Tianjin plant, which is in Komatsu, Ishikawa in Japan and has developed continuously, Its merits being recognized in "Journal of Quality Vol. 23, no. 1 (2016).QC Story Methodology is a tool that has its roots in TQM (Total Quality Management), starts from the general principle of continuous improvement - PDCA and consists of 7 steps:•...Read this article...

Data collection plan

Data collection is usually the most time consuming process and the most resources in the measuring process. This step is very important because the quality of this will have an impact on the following decision-making process, in particular to the analysis of the data.Data collection plan is a document that makes us sure that all team members speak about the same parameters, that information is properly transmitted to people in the organization in order to receive and collect the exactly data...Read this article...

Statistical techniques using Minitab and Qdas

In the production process, machines, peoples, materials, methods and environment lead to fluctuations in the results accuracy. Normal fluctuations have less impact on product quality and it is technically inevitable but abnormal fluctuations has more impact and lead to defects.SPC – Statistical process control is a process control methodology using statistical methods and was invented for the first time using control charts at 1924 at Bell Laboratories in USA.SPC is widely applied to...Read this article...

PDCA, 8D or Six Sigma

Problems are seen in everyday life as a real pain and something to be avoided by fair means or foul. In business, problems can lead to low productivity, poor quality, high costs and ultimately loss of customers if the problems are not dealt with rapidity and totally prevented reappearance.When referring to methodologies for solving problems and not to the tools themselves, here are the most common methods for solving problems: PDCA, Six Sigma (DMAIC), 8D.PDCA is a methodology of solving...Read this article...

Techniques of improvement often used

Between the managerial processes components of quality management, continuous quality improvement has a dominant role in reducing costs and in the economic growth of organizations. Continuous improvement refers primarily to improve the process and is used to identify, analyze and improve existing processes in an organization to achieve goals and objectives.Depending on the complexity of the problems, degree of staff involvement, with or without statistical methods, methodologies used most in...Read this article...

Selection of Improvement Methods

There is a large variety of methods to apply in improvement projects. Their various possible permutations can make it difficult for a company to choose the best approach for its project-related and organizational characteristics. Solving problems, starting with the simplest and ending with the organizational desire to become a world - class organization drives to implementation of some improvement methods which increase competitiveness and help companies to satisfy their customers.Six Sigma,...Read this article...

Six Sigma in energy production

Examples of measurable indicators for the specific activity of transport can be: primary energy intensity, CO2 intensity, efficiency of the power plants, specific energy consumption, etc.An example of a successful project using Six Sigma is “Reducing sulfur oxide emissions from burning coal in power plants “. This project solved the problem of streamline of activities and reduce the negative influence of environment. The key indicator which give the performance of the process and...Read this article...

Six Sigma in energy transportation

Examples of measurable indicators for the specific activity of transport of energy can be: Quantity of electricity delivered, coefficient of losses, average unavailability in time of facilities, line length unavailable for event, transformer / auto transformer nominal apparent power (MVA), the duration (time in hours) of unavailability to the event, etc.An example of a successful project using Six Sigma is “decrease downtime “. The key indicator which give the performance of the...Read this article...

Continuous improvement in aquisitions

Aquisition process, like any process, is composed of a sequence of operations that transform inputs into outputs and adds value. When we talk about entries we think of course about suppliers and performance of their products, including their evaluation, which is also an IATF 16949 standard requirement.Therefore, evaluating of suppliers and monitoring their performance are the main actions, through we can make the exit or exits from our production process to be performants.Read this article...

Moderating workshops

The training process is a complex process that begins with a theoretical part but which ultimately focuses on putting it into practice. The most conclusive example is the development of an 8D Report based on the knowledge gained in 8D courses, building statistical control charts after the Statistical Process Control courses or Gage R & R study after attending the Measurement System Analysis courses.Moderating Workshops course contains guidelines and tools that can be used successfully in...Read this article...

Six Sigma in administration

Six Sigma can help to improve services provided by the administration or to reduce costs and compliance with the budgets granted. Examples of measurable indicators can be: time of deliver of a service (example an approval of document of urbanism), time for fulfillment of some objectives, % of objectives fulflled from total, time for invoices payment, etc.For example: A Six Sigma project could be "Reducing the time of issuing the building permit." This process goes through several phases:...Read this article...

Six Sigma in the food industry

The food industry is extremely complex. This industry has some features linked by the nature of the raw materials processed and the finished products obtained. Raw materials are mostly biological products, perishable and degradable. Starting from here we can conclude the need for improvements that can be done with Six Sigma. Six Sigma is a data-driven systematic approach. DMAIC methodology - Define, Measure, Analyze, Improve & Control is used to improve the existing process.An example of a...Read this article...