REFA vs MTM norming

The time norm is the time allotted for the performance of a work task by a worker with a certain qualification, under certain technical and organizational conditions. It's the most important norm because other types of norms are determined based on it.

It is mainly applied for the rationing of the labor force of workers engaged in performing heterogeneous work and is expressed in units of time, such as: seconds, minutes or hours per unit of production.

The measuring instruments used in the case of norming are timers (mechanical or electronic) or video systems.

The timing mode is as follows:

- The operator/operators participating in the norming is established

- The compliance and availability of materials, equipment and the level of training of the operators are checked

- The purpose of using the data is established

- The timing is done with a measuring device, usually a stopwatch

- The efficiency of the operator that is timed is evaluated

- The data obtained is recorded and documented in specific forms (registration form)

The quality of the evaluation depends on the ability, professional training and experience of the observer.

The norming method by timing can be achieved only in the phases of zero series or start production. It cannot be achieved at the stages of planning the production lines. It can be applied both for manual production times, as well as for process times or waiting times.

The norming method can be used both for mass production, in series, or uniquely, both for cycles of short duration and for cycles of long or very long duration.

In general, there are several standards for the use of norming, the most commonly used being REFA, MTM or some variants derived from them.

REFA

REFA (Reich Committee for Working Time Determinationies) is a German organization designed to create a method to organize the workplace and develop it and to determine production times. It was founded in 1924 by the German Association of Engineers.

The method focuses both on the determination and evaluation of the time data and on the optimization of the work processes following the norming. REFA generally consists of standardizing production operations and evaluating the yield in the case of manual work.

In general, when we talk about norming, we refer to time, production or personnel norms.

MTM

MTM stands for the abbreviation Methods-T ime Measurement and is a method of determining the (manual) movement times, used mainly in industrial environments, for the analysis of the methods used to perform any manual operation or task.

The method was founded in 1926 under the name of MTA (Motion Time Analysis) and has been developed over time on several branches depending on the type of production applicable (MTM-1, MTM-2, MTM-UAS, MTM-MEK...)

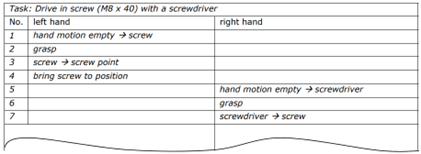

MTM-1 is the most used method and is used for mass production, with relatively short cycle times < 1 min. MTM-1 is a procedure that analyzes any manual operation at the level of basic movements (Reach-G rasp-M ove-P osition-R elease). In addition to these basic movements, MTM can also determine the times for visual inspections (Eye Travel, Eye Focus), body movements (Foot/Leg motions, Turn Body, Walk, Bend, Sit, Stand...).

For all these movements, there is a predetermined time, depending on the distance of the movement, the degree of control, the type of movement, the force.

MTM cannot be used to determine process times or waiting times, which must be determined by other methods (timing, video recording...).

The advantages of using this method:

- It can be determined from the planning stage

- In MTM analyses it is not necessary to calculate or determine the yield with which the associate works, this being always 100%

- MTM analysis helps to break down manual times on each hand separately

- We can parallelize the activities of the hands

- It helps to define the optimal method of work, by eliminating unnecessary movements, simplifying them, adopting the most favorable sequence of movement

- After completing the MTM analysis, you can easily optimize the working method, in order to reduce the working time

- Helps define workstation design in the planning phase

- Helps precalculate production times

Both methods are correct and used in the norming of time, and itis important to choose the optimal one for determining the times, depending on the type of production, the phases of the project and the qualification of the personnel who perform the time study.